Bioeletricity

As it grows, sugarcane converts sunlight into chemical energy which it stores inside the plant. Each of the following main plant components contains approximately one-third of this stored energy:

As it grows, sugarcane converts sunlight into chemical energy which it stores inside the plant. Each of the following main plant components contains approximately one-third of this stored energy:

Juice– The sweet liquid inside sugarcane stalks containing sucrose used to produce sugar and ethanol.

Bagasse– The dry, fibrous residue left after sugarcane is crushed. One ton of cane produces about 270 kilos of bagasse, making large dunes of bagasse a typical feature of Brazilian cane processing mills.

Straw– The tops and leaves of sugarcane stalks.

Brazilian sugarcane mills learned to harness the energy stored in bagasse by burning it in boilers to produce bioelectricity. As a result, these mills are energy self-sufficient, producing more than enough electricity to cover their own needs. A growing number of mills also generate a surplus, which is sold to distribution companies and helps to light up numerous cities throughout Brazil. In 2018, sugarcane mills supplied more than 21,500 GWh, or 4 percent of Brazil’s electricity requirements, thanks to bioelectricity.

SUGARCANE STRAW: A GROWTH OPPORTUNITY

For centuries, sugarcane fields around the world have been burned to eliminate the straw, drive away snakes and other potentially poisonous animals, and make it easier for workers to cut the cane by hand. While it was an essential step to cane harvesting, it wasted one-third of the plant’s energy.

Mechanized harvesting changes this equation by eliminating the need for burning the field. With mechanization, sugarcane straw is preserved and its energy can be harnessed in one of two ways:

More electricity. The straw can be burned alongside bagasse in high-efficiency boilers to produce even more bioelectricity. Experts estimate that with full utilisation of sugarcane residues, bioelectricity could reach 146,000 GWh. That would be enough energy to cover 30 percent of Brazil’s electricity needs. Or looked at another way, it could power an entire country the size of Sweden or Mexico.

More ethanol. Straw can also be used as an input to produce cellulosic ethanol. Once perfected at commercial scale, cellulosic ethanol holds the potential to double the volume of fuel coming from the same amount of land planted with sugarcane.

Mechanization is expanding rapidly and already exceeds 90 percent of the harvest in Brazil’s top cane producing state, São Paulo.

BIOELECTRICITY BENEFITS

• Low environmental impact

• Producers can obtain carbon credits

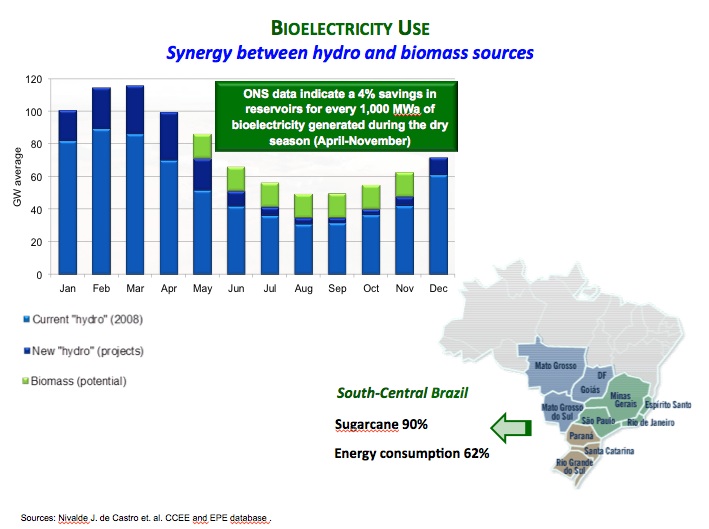

• Complementary to hydroelectricity

This last point is particularly important for Brazil because a large portion of the country’s electricity comes from hydro dams. The sugarcane harvesting period, when most biomass is available, coincides with the dry season. So when hydroelectric power stations sometimes have to reduce output because of low water levels in their reservoirs, sugarcane bioelectricity is most abundant. Besides being complementary with hydroelectricity, the majority of sugar and ethanol plants are located fairly close to the more populous regions of Brazil, where electricity demand is the highest.

did you know?

UNICA's contribution to the EU public consultation on the sustainability of bioenergy

CDM – Consolidated Methodology for Electricity Generation from Biomass Residue

Consolidated Baseline Methodology for Grid-Connected Electricity Generation from Renewable Sources

Ethanol and Bioelectricity: Sugarcane in the Future of the Energy Matrix