Best pratices

The Brazilian sugarcane industry employs modern agronomic management practices to enhance productivity and protect the environment. Key features of Brazil’s sustainable approach to cultivation and processing include:

LOW SOIL EROSION

Brazilian sugarcane fields have relatively low levels of soil loss, due in part to the semi-perennial nature of sugarcane. The same plant will grow back many times after it is cut and its cane juice is extracted. In fact, sugarcane is typically only replanted every six or seven years.

The Brazilian industry also emphasizes farming techniques that preserve soil stability while yielding approximately 85 tons of sugarcane per hectare. Strategies include:

– No-till production systems

– Crop rotation with soybeans or peanuts

– Green fertilization by planting cover crops such as Crotalaria juncea or using leftover sugarcane straw after mechanized harvesting as ground cover

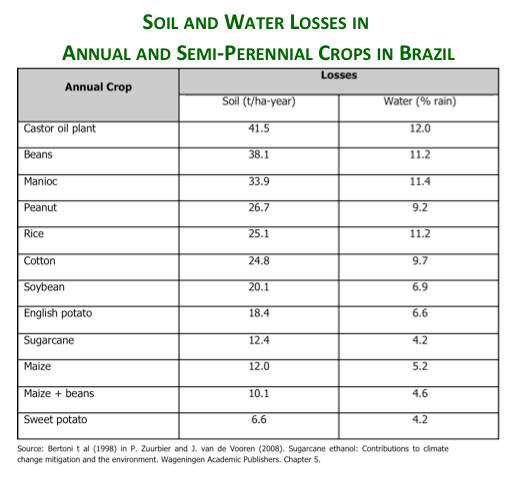

Thanks to these responsible agricultural practices, soil erosion in sugarcane fields is minimal when compared to many other crops such as rice and soybeans (For more read the “Environmental sustainability of sugarcane ethanol in Brazil” study). In some regions of the country, sugarcane has been produced on the same soil for more than 200 years with continuous yield and soil carbon increases.

MINIMUM WATER USE

Thanks to abundant and reliable rainfall, sugarcane is usually not irrigated in South-Central Brazil, where most of the country’s crop is grown. Water accounts for more than two-thirds of sugarcane’s weight, so a significant amount of water actually comes to the mill inside the cane itself.

Brazilian mills emphasize efficiency and have reduced the water used during industrial processing by more than 70% (to 1.4 m³ per ton) during the past two decades. New technologies will soon allow for a more efficient use of the water contained in the cane, and water withdrawal could be reduced to 0.5 m3/ton. Today, nearly 95% of the water consumed by a typical mill is later treated and re-used in the industrial process, with the objective to eliminate water discharge.

REDUCED USE OF AGROCHEMICALS

Application of pesticides on Brazilian sugarcane fields is negligible and use of fungicides practically nonexistent. Major diseases that threaten sugarcane are fought through biological control, introducing natural enemies to fight pests and advanced genetic enhancement programs.

Brazilian sugarcane growers also apply relatively few industrialized fertilizers, using on average 75 kilograms per hectare. That’s 50% less than the amount typically applied to corn in the United States and 30% less than what’s used for beet sugar in Europe.

Brazilian sugarcane needs fewer chemicals due to the innovative use of organic fertilizers created during sugarcane processing. For instance, sugarcane mills recover residues called filter cake (which is rich in phosphorus) and vinasse (loaded with potassium, organic matter and other nutrients), which they use in place of traditional fertilizers.

ENVIRONMENTAL PROTECTION

The gradual eradication of pre-harvest sugarcane field burning is key to reduce local air pollution and improve air quality.

For centuries, sugarcane fields around the world have been burned to remove sugarcane straw (the plant’s tops and leaves), drive away snakes and other potentially poisonous animals, and make it easier for workers to cut the cane by hand. However, technological advances and environmental concerns have increased demand for mechanized harvesting because it eliminates the need to burn the field.

Mechanization already exceeds 95 percent of the harvest in São Paulo, Brazil’s top cane-producing state. It is the only means of harvesting in São Paulo in areas that can be mechanized since 2017, thanks to the so-called Green Protocol.

Besides eliminating field burning, the 173 mills (out of the 178 total located in São Paulo) and 29 associations of sugarcane suppliers who signed the Green Protocol have committed to protect and recover 280,000 hectares of land alongside streams and riverbanks.

Over the last seven years, producers from Brazil´s Centre-South have invested around US$ 4.5 billion in equipment purchases to increase mechanized harvesting of sugarcane.

Compliance with the Green Protocol’s directives is policed by the government, with all relevant documents and certificates made available to the public (in Portuguese). A similar protocol was applied in the State of Minas Gerais since August 2008.

Nationally, a federal decree prohibits pre-harvest field burning as of 2018 on large farms that can be mechanized. In the meantime, sugarcane producers must obtain an authorization from the State government each time they intend to burn sugarcane fields. During dry periods, sugarcane burnings are prohibited during the day to protect the health of surrounding communities.

Finally, stricter enforcement, new emission standards for bioelectricity generators and replacement of old boilers with more efficient units have contributed to an ongoing reduction of smoke stack emissions from sugarcane mills.

LEARN MORE

The following studies provide more detailed information about sugarcane agricultural practices:

Sugarcane ethanol: Contributions to climate change mitigation and the environment – Chapter 5

Sugarcane-based bioethanol: Energy for sustainable development – Chapter 7.1

Sugarcane’s energy: Twelve studies on Brazilian sugar cane agribusiness and its sustainability – Chapter 3 to 10

WHAT'S NEW

Sugarcane harvest for South Central Brazil for the second half of November 2020 Read on